You’re likely underestimating how much a well-designed pathway transforms your landscape’s functionality and visual appeal. When you select gravel, edging, and drainage solutions thoughtfully, you’ll create routes that guide visitors while preventing costly maintenance issues. But here’s what most homeowners overlook: the foundation preparation and fabric installation determine whether your pathways remain pristine or deteriorate within seasons.

Gravel Pathway Installation Methods

When you’re planning a gravel pathway, you’ll want to start with proper site preparation to guarantee longevity and functionality. First, excavate the area to a depth of 4-6 inches, ensuring adequate drainage. Lay landscape fabric to suppress weeds and prevent gravel migration into surrounding soil.

Your pathway design should account for slope and width requirements—typically 2-3 feet for single-file passages. Establish sturdy edging using metal, wood, or plastic borders to maintain structural integrity.

For gravel color selection, consider complementary tones that coordinate with your garden aesthetic and existing hardscaping. Select angular stones rather than rounded varieties, as they compact more effectively and resist displacement.

Apply gravel in 2-3 inch layers, compacting each layer with a hand tamper or mechanical plate compactor for ideal stability and durability.

Preparing the Foundation Base

Once you’ve excavated your pathway bed to the proper depth, you’ll need to establish a stable foundation base that’ll support the gravel layers above. Begin with thorough soil assessment to identify the existing soil composition and drainage characteristics. If you’re working with clay or compacted soil, you’ll want to loosen it slightly to improve water permeation. Compact the base layer using a hand tamper or mechanical compactor to create a firm, level surface. This foundation preparation prevents future settling and guarantees even weight distribution. Add a landscape fabric layer to separate the native soil from your gravel, which minimizes weed growth and maintains structural integrity. Proper foundation work eliminates common pathway problems like ruts, puddles, and uneven surfaces.

Choosing Appropriate Gravel Types

Because your pathway’s performance depends largely on material selection, you’ll want to evaluate gravel options based on size, composition, and drainage properties. Different gravel types serve distinct purposes: crushed stone provides stability and compacts firmly, while pea gravel offers comfort underfoot but requires edging containment. Angular rock fragments interlock effectively, reducing shifting, whereas rounded stones move more freely.

Consider gravel color variations to complement your landscape design. Lighter hues reflect sunlight and heat, while darker tones absorb warmth. Granite chips resist weathering better than limestone, which deteriorates faster. Evaluate your climate’s rainfall patterns—coarser materials drain quickly in wet regions, while finer grades suit drier areas.

Match gravel depth to traffic intensity: two to three inches for high-use pathways guarantees longevity and maintains proper compaction levels throughout seasons.

Edging Materials and Installation

Your gravel pathway‘s performance hinges not just on material selection but also on proper containment. You’ll find several edging options available, each offering distinct advantages. Metal edging provides durability and clean lines, while plastic alternatives offer flexibility and affordability. Wood edging delivers aesthetic appeal but requires regular maintenance. Composite materials combine longevity with visual appeal.

Installation techniques vary by material type. You’ll want to excavate a shallow trench along your pathway perimeter, positioning edging materials at soil level or slightly above. Secure metal edging with stakes driven firmly into the ground at 24-inch intervals. For plastic edging, use manufacturer-supplied fasteners or landscape pins. Wood edging requires sturdy posts anchored below the surface. Guarantee proper alignment before securing, as misalignment compromises both aesthetics and functionality.

Drainage System Installation Basics

Proper drainage is essential to preventing water accumulation beneath your gravel pathways, which can lead to erosion, settling, and premature deterioration. You’ll want to establish effective drainage designs that redirect surface runoff away from your pathway structure.

Start by sloping your pathway slightly—ideally 1-2% grade—to encourage water movement. Install a perforated drainage pipe beneath the gravel base layer, positioned in a shallow trench. This pipe channels excess moisture away from your pathway foundation.

You should also consider installing French drains along pathway edges if you’re working in poorly draining soil. Layer landscape fabric above the drainage pipe, then add your gravel base. This creates a complete drainage system that maintains pathway integrity and extends its lifespan considerably while preventing costly water-related damage.

Compact Soil Thoroughly First

Before you lay down gravel, you’ll need to compact the soil base to create a stable foundation that resists settling and displacement. Proper soil compaction techniques guarantee your pathway remains even and durable for years. You’ll want to use a hand tamper or mechanical compactor, working in layers of 2-4 inches. Make multiple passes over each section, applying consistent pressure throughout.

The benefits of compacting are substantial. Compression eliminates air pockets that cause uneven settling, prevents water pooling, and reduces maintenance needs. A well-compacted base distributes foot traffic weight evenly, extending your pathway’s lifespan. You’ll also notice improved drainage performance, as compacted soil channels water away effectively rather than allowing it to create soft spots or erosion patterns that compromise your pathway’s integrity and appearance.

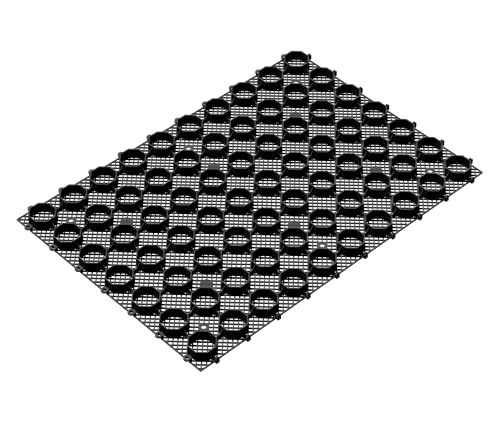

Landscape Fabric Prevents Weed Growth

After you’ve compacted the soil base, laying landscape fabric creates an essential barrier that suppresses weed germination and growth throughout your pathway. This permeable material allows water and nutrients to penetrate while blocking sunlight that dormant weed seeds need to sprout. You’ll experience significant landscape benefits by installing high-quality, UV-resistant fabric—it dramatically reduces maintenance demands and eliminates constant weeding sessions.

For ideal weed prevention, overlap fabric seams by six inches and secure edges with landscape staples or buried borders. The fabric’s durability extends your pathway’s functional lifespan considerably. Choose weights between three and five ounces for most applications; heavier grades withstand foot traffic better in high-use areas. This foundational layer protects your investment while maintaining a clean, professional appearance throughout the seasons.

Gravel Size Affects Stability

Once you’ve installed and secured your landscape fabric, selecting the right gravel size becomes critical to your pathway’s structural integrity and longevity. You’ll want to use angular gravel particles ranging from three-quarter to one-and-a-half inches, as these sizes interlock effectively and resist shifting. Implement proper gravel compaction techniques by using a hand tamper or mechanical compactor in multiple passes, creating a dense, stable base layer. For stability improvement strategies, consider combining different gravel grades—larger stones as your foundation with smaller pea gravel on top—which enhances weight distribution and drainage. You should compact each layer separately before adding the next. This layered approach prevents rutting, maintains proper pathway elevation, and greatly extends your garden pathway’s usable lifespan while minimizing maintenance demands.

Maintenance Requirements for Longevity

Maintaining your gravel pathway regularly is crucial to preserve the structural integrity you’ve established through proper installation and layering. You’ll need to rake your pathway quarterly to redistribute settled gravel and address compaction issues. Inspect drainage systems seasonally, clearing debris from edges and borders that might obstruct water flow. Apply fresh gravel annually to compensate for displacement from foot traffic and weather exposure. Your pathway upkeep routine should include removing weeds promptly to prevent root systems from destabilizing the base layers. Monitor for erosion patterns, particularly in high-traffic zones, and replenish material as needed. These longevity tips guarantee your pathway maintains functionality and appearance for years. Implement a documented maintenance schedule to track interventions and optimize resource allocation for sustained performance.

Seasonal Gravel Replenishment Schedule

Planning your gravel replenishment around seasonal cycles guarantees you’ll address material loss before it compromises pathway integrity. Spring and fall represent ideal windows for seasonal check-ups, when you can assess compaction and displacement from freeze-thaw cycles and heavy foot traffic.

Conduct thorough inspections quarterly to measure depth depletion rates specific to your pathway’s usage patterns. Most pathways require replenishment every 18-24 months, though high-traffic routes demand annual attention.

Establish relationships with reliable gravel sourcing vendors before depletion becomes critical. Order materials during off-peak seasons to secure better pricing and guarantee availability. Match replacement gravel to your original specifications regarding size, composition, and color for visual consistency.

Document replenishment dates and quantities in a maintenance log. This data-driven approach prevents emergency repairs while optimizing material expenditures.